|

More Super Hard Products Co., Ltd.

|

Diamond Dressing Roller Diamond Dressing Wheel

| Price: | 200.0 USD |

| Payment Terms: | T/T,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

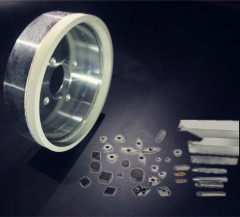

More Superhard 's diamond roller dressers are used for forming and dressing fired abrasive grinding wheel , CBN wheel and internal mounted pointed.

Diamond Dressing Roller, Diamond Dressing Wheel

More Superhard 's diamond roller dressers are used for forming and dressing fired abrasivegrinding wheel , CBN wheel and internal mounted pointed. Diamond profile roller dressershave high precision dressing efficiency and good straightness .Since these dressers are capable of accurate and speedy form dressing, they can effectively be used to mass produce work parts with a high degree of accuracy.

Diamond dressing wheel use method and characteristics:

Diamond dressing roller is a kind of efficient dressing tool for forming wheels/ especially, it is used for the dressing of complex surface and high precision forming surface. At present, electroforming and sintering method are the main two art for dressing roller making.

The application of the diamond dressing roller:

The dressing rollers can be widely used in the filed of automobile, tool machines, bearings,aviation and industry processing filed.

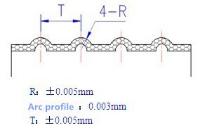

Diamond dressing roller Application | Picture Show | Drawing |

Corrugated rouer of packaging machine |  |  |

Curved vane of air-conditioning compressor |  |  |

Tap |  |  |

V-shape guide |  |  |

The advantages of the diamond dressing roller are as below:

1. High production efficiency, long service and work life, low dressing cost for a single grinding wheel

2. Ensure the precision of workpieces, stable roughness, reduce the inferior products largely

3. Dressing equipment is of simple structure, change less, reduce workload of operators.

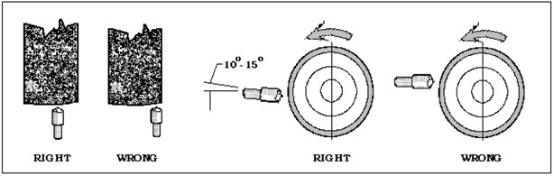

How to dressing diamond dressing roller?

DRESSING : Bring diamond to high point of grinding wheel. Turn on coolant. See that acopious amount is flowing on both diamond and wheel. Start traverse feed 18" to 30" perminute. Take two or more passes across face of wheel. (Stop here if rough dressing isdesired). To obtain finish dressing, continue from above. Change traverse fee to 6" to 15" perminute. Proceed with at least 2 passes at .001" penetration followed by one or two passes at.0005" penetration. (Stop here for good commercial finish). For super finish continue with oneor two passes without further penetration. Remove loose particles from face of wheel by using a small piece of hard wood or fiber.

Diamond dresser should be on the center line of grinding wheel or 1/32' below, never above.

To avoid wheel taper, position diamond dresser as near as possible to the area where the grinding is being performed. When completing last pass of dressing operation allow same to finish in the same direction each time.

For more information about our products,please contact me anytime!